CNC Brush Deburring: The Ultimate Solution For Precision Finishing

Cnc Brush Deburring: The Ultimate Solution for Precision Manufacturing

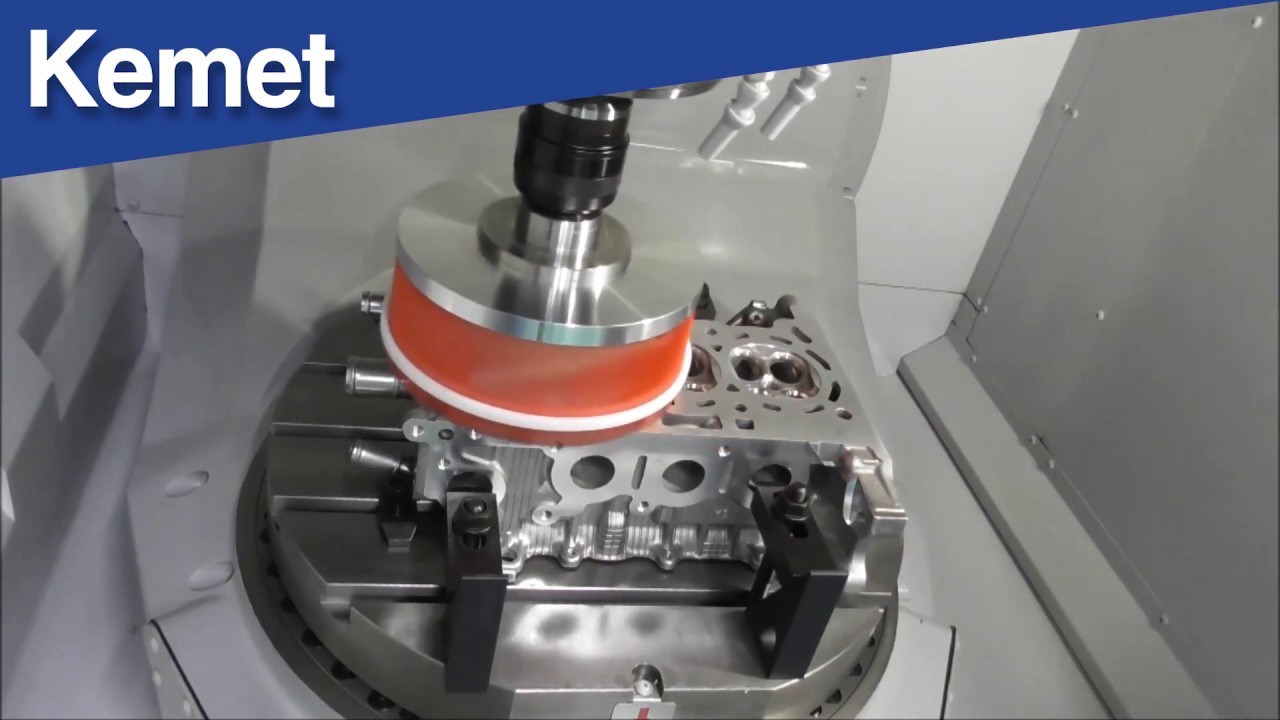

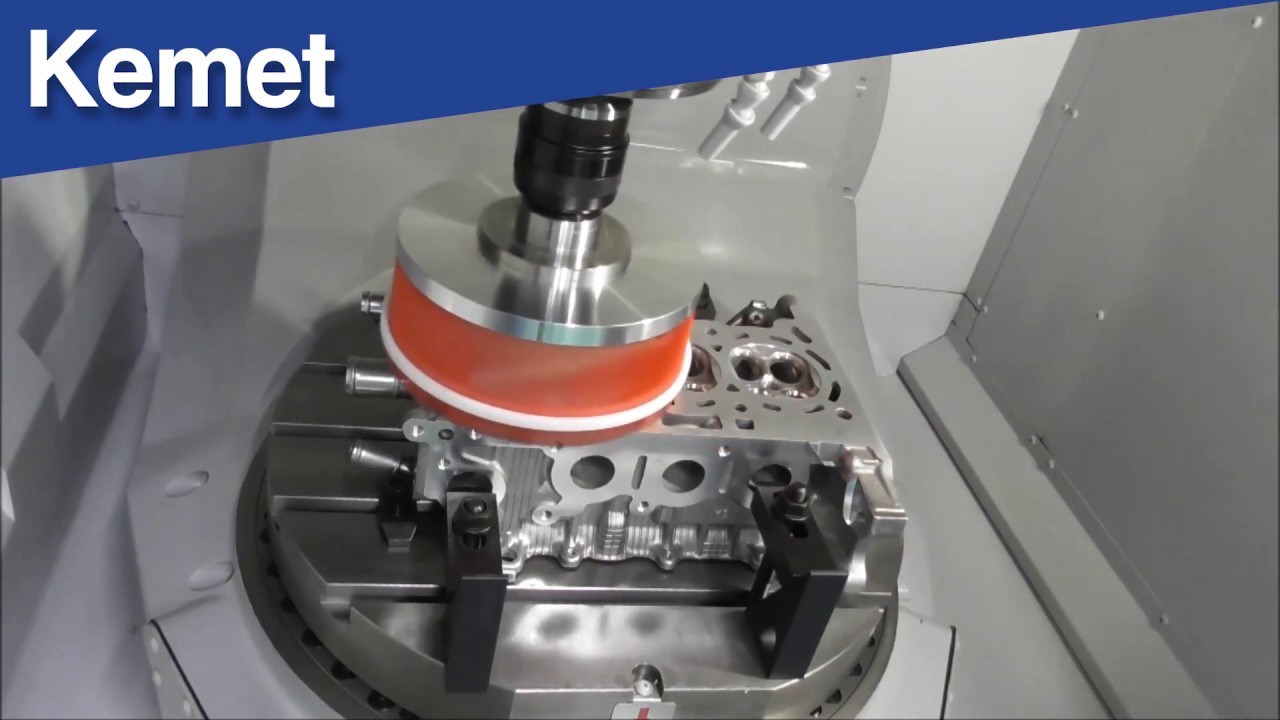

Cnc Brush Deburring is a mechanical process that removes burrs and sharp edges from machined parts in the manufacturing industry. This process is extremely important as it ensures that the final products are safe to use and meet the required quality standards. The process involves the use of a brush that rotates at high speeds and removes any unwanted debris from the surface of the parts. This article will provide a detailed overview of Cnc Brush Deburring and its benefits for precision manufacturing.

What is Cnc Brush Deburring?

Cnc Brush Deburring is a precision manufacturing process that removes burrs and sharp edges from machined parts. This process is used in various industries such as aerospace, automotive, medical, and electronics. The process involves the use of a brush that rotates at high speeds and removes any unwanted debris from the surface of the parts. The brush is made of high-quality materials and is designed to last for a long time.

2 Picture Gallery: CNC Brush Deburring: The Ultimate Solution For Precision Finishing

Who Needs Cnc Brush Deburring?

Cnc Brush Deburring is a crucial process for any business that deals with precision manufacturing. This process is used in various industries such as aerospace, automotive, medical, and electronics to ensure that the final products are safe to use and meet the required quality standards.

When is Cnc Brush Deburring Used?

Cnc Brush Deburring is used after the machining process to remove any burrs and sharp edges from the parts. This process is typically used for small to medium-sized parts that require high precision and accuracy. The process is also used for parts that require a smooth surface finish.

Where is Cnc Brush Deburring Used?

Cnc Brush Deburring is used in various industries such as aerospace, automotive, medical, and electronics. The process is typically used in manufacturing plants and factories to ensure that the final products are safe to use and meet the required quality standards.

Why Use Cnc Brush Deburring?

Cnc Brush Deburring is an important process that ensures that the final products are safe to use and meet the required quality standards. The process reduces the risk of injuries caused by sharp edges and burrs and ensures that the parts fit together perfectly. This process also improves the overall quality and appearance of the final products.

How Does Cnc Brush Deburring Work?

Cnc Brush Deburring involves the use of a brush that rotates at high speeds and removes any unwanted debris from the surface of the parts. The process is automated and requires minimal human intervention. The parts are loaded onto a machine that uses a brush to remove any burrs and sharp edges from the surface of the parts. The process is fast and efficient and ensures that the final products meet the required quality standards.

Cnc Brush Deburring FAQ:

Q: What type of parts can be deburred using Cnc Brush Deburring?

A: Cnc Brush Deburring can be used to remove burrs and sharp edges from small to medium-sized parts that require high precision and accuracy.

Q: What materials can be deburred using Cnc Brush Deburring?

A: Cnc Brush Deburring can be used to remove burrs and sharp edges from various materials such as aluminum, steel, brass, and titanium.

Cnc Brush Deburring Design and Quality:

Cnc Brush Deburring machines are designed to be durable and long-lasting. The brushes are made of high-quality materials and are designed to last for a long time. The machines are also designed to be easy to use and require minimal maintenance.

Cnc Brush Deburring Performance and Versatility:

Cnc Brush Deburring machines are designed to be fast and efficient. The process is automated and requires minimal human intervention. The machines are also versatile and can be used to remove burrs and sharp edges from various materials such as aluminum, steel, brass, and titanium.

Cnc Brush Deburring Longevity and Value:

Cnc Brush Deburring machines are designed to be durable and long-lasting. The machines are also cost-effective and provide a high return on investment.

Cnc Brush Deburring Pros and Cons:

Pros:

Removes burrs and sharp edges from machined parts

Improves the overall quality and appearance of the final products

Reduces the risk of injuries caused by sharp edges and burrs

Cons:

Requires an investment in machinery

May not be suitable for very large parts

Requires regular maintenance

Cnc Brush Deburring Price and Discount:

Cnc Brush Deburring machines can range in price from a few thousand dollars to over $100,000. The cost of the machines depends on various factors such as the size of the machine, the type of brush, and the level of automation.

Conclusion:

Cnc Brush Deburring is a crucial process for any business that deals with precision manufacturing. This process ensures that the final products are safe to use and meet the required quality standards. The process involves the use of a brush that rotates at high speeds and removes any unwanted debris from the surface of the parts. The machines are designed to be durable, efficient, and cost-effective. Overall, Cnc Brush Deburring is an essential process for anyone looking to produce high-quality products that meet the required quality standards.

This post topic: Brush