Revamp Your Conveyor System With Efficient Conveyor Belt Brush Scrapers: Get Yours Now!

Conveyor Belt Strokes.us/brush/’>Brush Scrapers: The Ultimate Solution for Belt Cleaning

Conveyor systems have become an integral part of various industrial processes. They are used to transport goods, materials, and products from one place to another. However, over time, these systems can accumulate dirt, dust, and debris, which can cause significant issues if left uncleaned. This is where conveyor belt brush scrapers come in handy.

What are Conveyor Belt Brush Scrapers?

Conveyor belt brush scrapers are mechanical devices that are used to clean conveyor belts. They are designed to remove dirt, dust, and debris from the surface of the belt, ensuring that it runs smoothly and efficiently. These devices are comprised of bristles, which come in various materials, such as nylon, polypropylene, or steel.

3 Picture Gallery: Revamp Your Conveyor System With Efficient Conveyor Belt Brush Scrapers: Get Yours Now!

Who Needs Conveyor Belt Brush Scrapers?

Conveyor belt brush scrapers are essential for any industry that uses conveyor systems. These include mining, material handling, food processing, and manufacturing, to name a few. They can be used on any type of conveyor belt, including flat belts, troughed belts, and cleated belts.

When Should Conveyor Belt Brush Scrapers be Used?

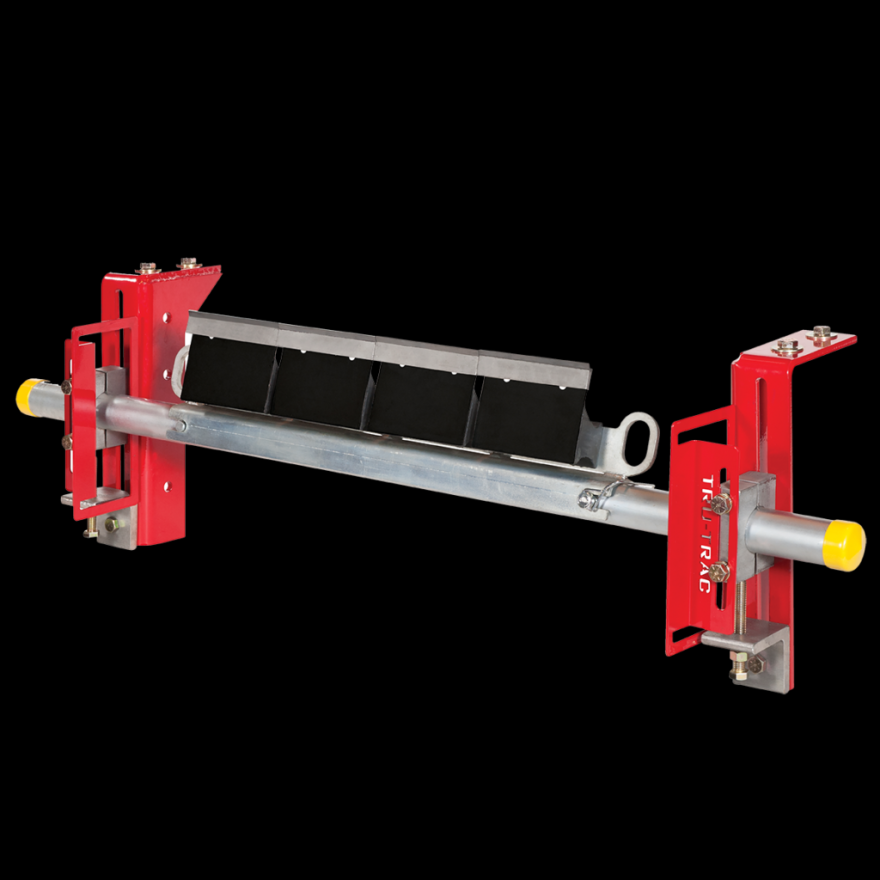

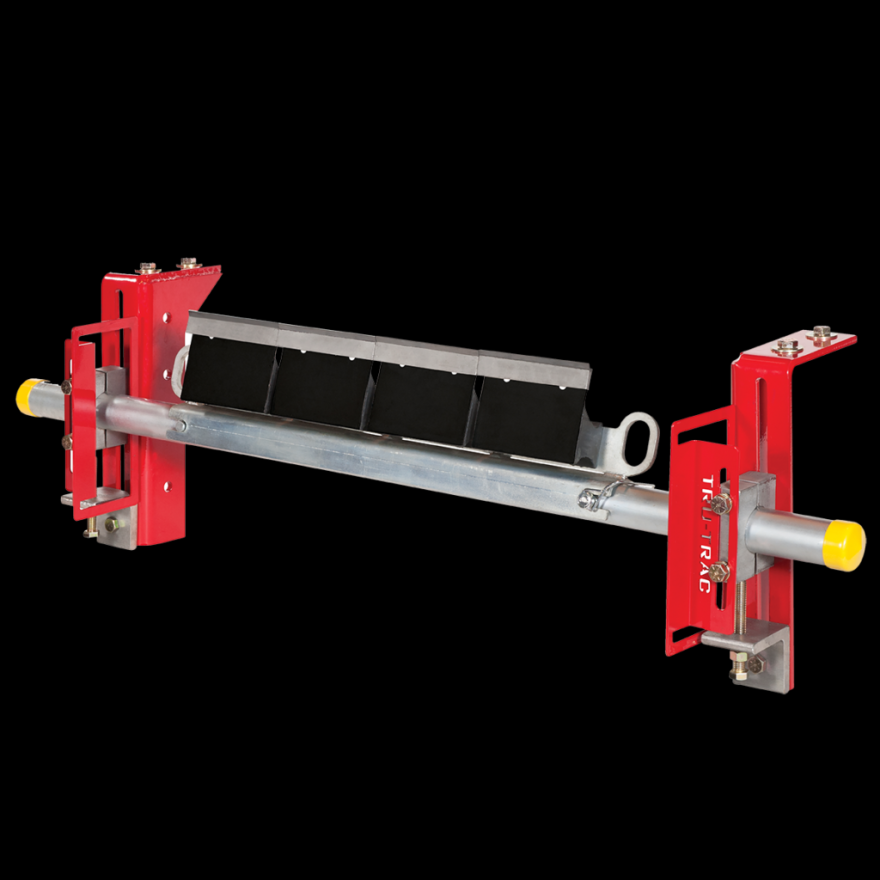

Image Source: tru-trac.com

Conveyor belt brush scrapers should be used regularly to ensure that the conveyor system runs smoothly. They can be used during operation or during downtime for maintenance purposes. Ideally, conveyor belt brush scrapers should be used daily to prevent the buildup of dirt and debris, which can cause the belt to slip or wear out prematurely.

Where Can Conveyor Belt Brush Scrapers be Used?

Conveyor belt brush scrapers can be used in any industry that uses conveyor systems. They are suitable for use in a wide range of environments, including dusty, dirty, or wet conditions. They can be used in both indoor and outdoor settings and on various types of conveyor belts.

Why are Conveyor Belt Brush Scrapers Important?

Conveyor belt brush scrapers are important because they help to prolong the life of the conveyor belt. They prevent the buildup of dirt and debris, which can cause premature wear and tear. They also help to improve the efficiency of the conveyor system. A cleaner belt means that the system runs smoothly, preventing downtime and reducing maintenance costs.

How do Conveyor Belt Brush Scrapers Work?

Image Source: dynaeng.com.au

Conveyor belt brush scrapers work by removing dirt and debris from the surface of the belt. As the belt moves, the bristles on the scraper come into contact with the surface and remove any contaminants. The dirt and debris are then deposited into a collection container, where they can be disposed of safely.

Types of Conveyor Belt Brush Scrapers

There are several types of conveyor belt brush scrapers, including primary and secondary scrapers. Primary scrapers are installed at the head pulley of the conveyor system and are designed to remove the bulk of the dirt and debris from the belt. Secondary scrapers are installed after the head pulley and are used to remove any remaining contaminants.

Materials Used in Conveyor Belt Brush Scrapers

Conveyor belt brush scrapers can be made from various materials, including nylon, polypropylene, and steel. Nylon and polypropylene bristles are suitable for use in dry environments, while steel bristles are more durable and can be used in wet or harsh conditions.

Specifications of Conveyor Belt Brush Scrapers

Image Source: martin-eng.com

Conveyor belt brush scrapers come in various sizes and specifications. The size of the scraper is determined by the width of the conveyor belt. The bristle length and density also vary depending on the type of material being conveyed and the level of cleanliness required.

Tips and Tricks for Using Conveyor Belt Brush Scrapers

Here are some tips and tricks for using conveyor belt brush scrapers:

Ensure that the scraper is installed correctly and positioned at the correct angle.

Inspect the scraper regularly to ensure that it is working properly.

Clean the scraper and collection container regularly to prevent the buildup of dirt and debris.

Replace worn or damaged bristles to maintain the effectiveness of the scraper.

Benefits of Conveyor Belt Brush Scrapers

The benefits of using conveyor belt brush scrapers include:

Improved efficiency of the conveyor system

Reduced maintenance costs

Increased lifespan of the conveyor belt

Reduced downtime

Improved safety by reducing the risk of slips and falls

Design and Quality of Conveyor Belt Brush Scrapers

Conveyor belt brush scrapers are designed to be durable and long-lasting. They are made from high-quality materials and are designed to withstand harsh environments. The bristles are carefully selected to ensure that they are effective at removing dirt and debris from the conveyor belt.

Durability and Performance of Conveyor Belt Brush Scrapers

Conveyor belt brush scrapers are designed to be durable and perform well in a variety of conditions. They are tested to ensure that they can withstand high levels of wear and tear. The performance of the scraper is closely monitored to ensure that it is effective at removing dirt and debris from the conveyor belt.

Versatility and Longevity of Conveyor Belt Brush Scrapers

Conveyor belt brush scrapers are versatile and can be used in a variety of industries and settings. They are designed to last for years, requiring minimal maintenance. The longevity of the scraper is dependent on the environment in which it is used and how often it is inspected and cleaned.

Value and Price of Conveyor Belt Brush Scrapers

The value of conveyor belt brush scrapers is evident in the improved efficiency and lifespan of the conveyor system. The price of the scraper will vary depending on the size and specifications. However, the cost is minimal compared to the cost of repairing or replacing a damaged conveyor belt.

Pros and Cons of Conveyor Belt Brush Scrapers

Here are some pros and cons of conveyor belt brush scrapers:

Pros:

Improves the efficiency of the conveyor system

Reduces maintenance costs

Increases the lifespan of the conveyor belt

Reduces downtime

Improves safety

Cons:

May require frequent cleaning

May need to be replaced periodically

May not be effective for all types of dirt and debris

Conclusion

Conveyor belt brush scrapers are an essential component of any conveyor system. They are designed to remove dirt, dust, and debris from the surface of the belt, improving its efficiency and lifespan. They are suitable for use in a variety of industries and settings and are available in various sizes and specifications. While they may require periodic maintenance, the benefits of using conveyor belt brush scrapers far outweigh any drawbacks.

As someone who has used conveyor belt brush scrapers in the past, I can attest to their effectiveness in keeping the conveyor system running smoothly. I would highly recommend them to anyone who wants to improve the efficiency and lifespan of their conveyor belt.

This post topic: Brush