The Ultimate Guide To Understanding The Stroke Of A Hydraulic Cylinder: Maximize Your Machinery Performance Now!

Exploring the Stroke of Hydraulic Cylinder

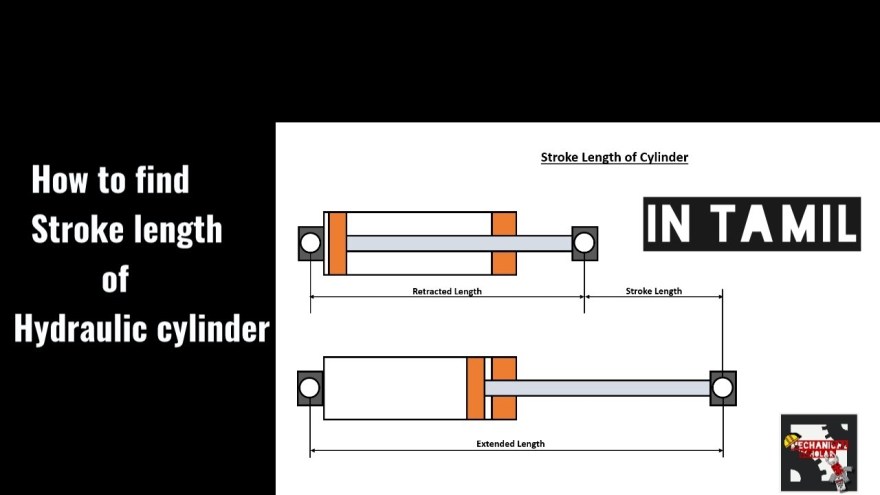

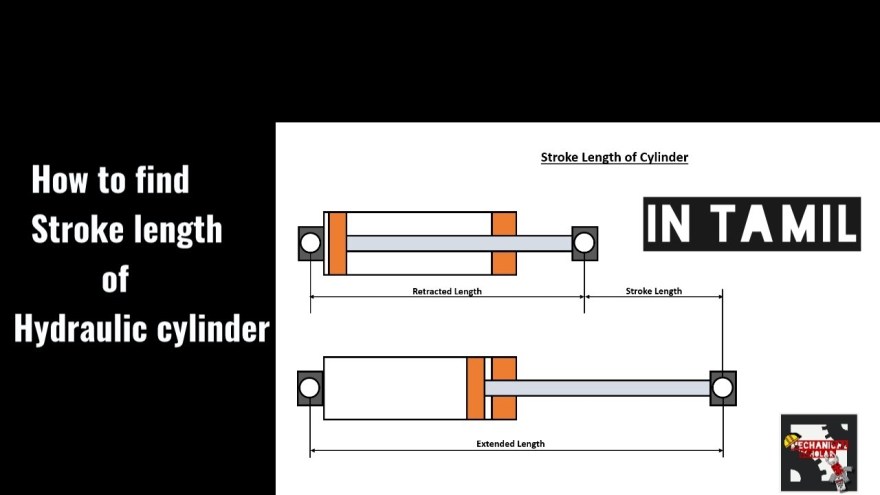

Stroke of Hydraulic Cylinder is a crucial component of hydraulic systems that helps in converting the pressure of fluid into linear motion. This stroke is the distance that the piston travels inside the cylinder while performing a particular task. Whether you are a hydraulic system enthusiast or a curious individual, understanding the stroke of hydraulic cylinders can help you grasp the working of this system better. In this article, we will explore everything you need to know about the stroke of hydraulic cylinders and related keywords like hydraulic systems, hydraulic pumps, hydraulic valves, and more.

What is a Hydraulic Cylinder?

A hydraulic cylinder is a mechanical actuator that generates force by transforming the pressure of hydraulic fluid into linear motion. These cylinders are widely used in various hydraulic systems, including construction equipment, industrial machinery, and material handling equipment. A hydraulic cylinder consists of a cylindrical barrel, a piston, a rod, and end caps. The piston is tightly sealed inside the cylinder, and the rod extends through one end of the cylinder to connect with the load.

3 Picture Gallery: The Ultimate Guide To Understanding The Stroke Of A Hydraulic Cylinder: Maximize Your Machinery Performance Now!

Who Needs Hydraulic Cylinders?

Hydraulic cylinders are widely used in various industries and applications that require linear motion. Some of the common sectors where hydraulic cylinders are used include construction, agriculture, automotive, and manufacturing. These cylinders are crucial in machines that require heavy lifting or pushing, such as excavators, bulldozers, and forklifts. Moreover, hydraulic cylinders are also used in industrial machinery like presses, metalworking equipment, and plastic molding machines.

When to Use Hydraulic Cylinders?

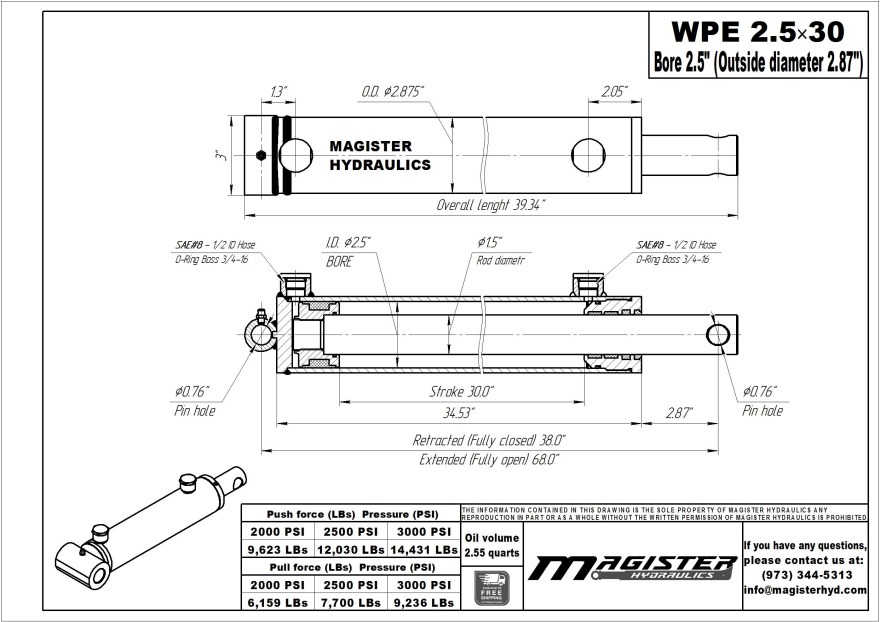

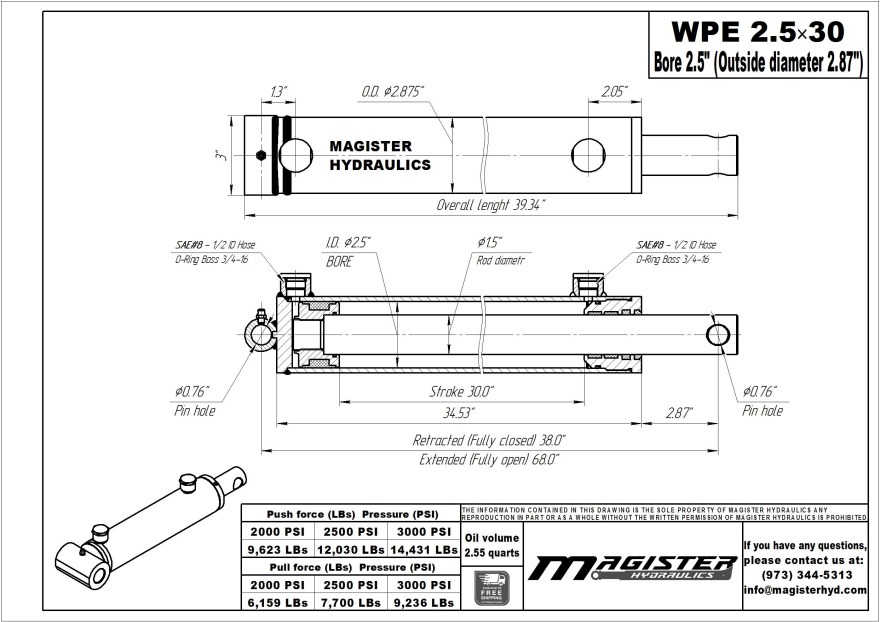

Image Source: magisterhyd.com

Hydraulic cylinders are typically used when you need to generate high force with relatively low energy input. These cylinders are ideal for heavy-duty applications that require consistent and precise linear motion. Moreover, hydraulic cylinders are also suitable for applications that require high speed, accuracy, and control. However, it is essential to choose the right hydraulic cylinder for your application based on its size, stroke, and other specifications.

Where to Find Hydraulic Cylinders?

Hydraulic cylinders are widely available in various sizes and types, and you can find them in local hydraulic shops, online stores, and manufacturers. However, it is crucial to choose a reputable supplier or manufacturer that offers reliable and high-quality hydraulic cylinders. Moreover, you should also consider the after-sales support, warranty, and technical assistance before making a purchase.

Why Choose Hydraulic Cylinders?

Hydraulic cylinders offer numerous benefits over other types of linear motion systems, such as mechanical and pneumatic systems. These benefits include high force generation, smooth operation, consistency, precision, and control. Moreover, hydraulic cylinders are also highly durable, reliable, and require minimal maintenance. Therefore, if you need to perform heavy-duty tasks that require consistent and precise motion, hydraulic cylinders are an ideal choice.

How to Select the Right Hydraulic Cylinder?

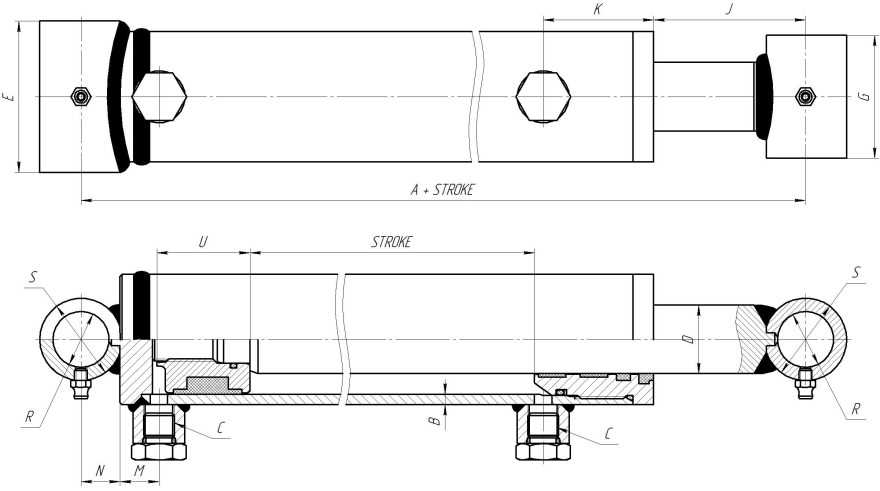

Image Source: magisterhyd.com

Selecting the right hydraulic cylinder depends on various factors such as the load capacity, stroke length, operating pressure, and bore size. Moreover, you should also consider the type of mounting, seal options, and materials used in the cylinder. Therefore, it is crucial to consult with a hydraulic expert or manufacturer before selecting a hydraulic cylinder for your application.

What are the Types of Hydraulic Cylinders?

Hydraulic cylinders are available in various types based on their construction, mounting style, and function. Some of the common types of hydraulic cylinders include single-acting cylinders, double-acting cylinders, telescopic cylinders, tie-rod cylinders, and welded cylinders. Each type has its unique features and benefits, and you should select the right type based on your application’s requirements.

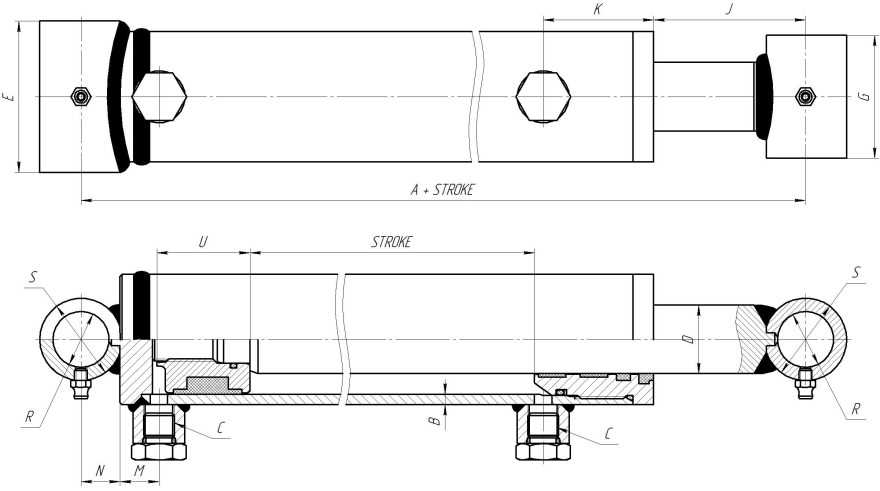

What are the Different Components of a Hydraulic Cylinder?

A hydraulic cylinder consists of several components, including a cylindrical barrel, a piston, a rod, and end caps. The barrel is the outer tube that houses the piston and the rod, while the piston is the component that generates the linear motion. The rod is the part of the cylinder that extends from one end to connect with the load, while the end caps are the covers that seal the cylinder’s ends.

What are the Materials Used in Hydraulic Cylinders?

Image Source: ytimg.com

Hydraulic cylinders are typically made of high-strength materials that can withstand the high pressure and forces generated by the hydraulic system. Some of the common materials used in hydraulic cylinders include steel, aluminum, bronze, and stainless steel. The material selection depends on the application’s requirements, such as load capacity, operating temperature, and corrosion resistance.

What Are the Benefits of Using Hydraulic Cylinders?

Hydraulic cylinders offer numerous benefits over other types of linear motion systems, such as mechanical and pneumatic systems. These benefits include high force generation, smooth operation, consistency, precision, and control. Moreover, hydraulic cylinders are also highly durable, reliable, and require minimal maintenance. Therefore, if you need to perform heavy-duty tasks that require consistent and precise motion, hydraulic cylinders are an ideal choice.

What are the Disadvantages of Using Hydraulic Cylinders?

Hydraulic cylinders have a few disadvantages, such as the high initial cost, the need for a hydraulic power unit, and the potential for oil leaks. Moreover, hydraulic cylinders also require regular maintenance and inspection to ensure optimal performance and prevent failures. However, these disadvantages are minor compared to the benefits that hydraulic cylinders offer.

What is the Price of Hydraulic Cylinders?

The price of hydraulic cylinders varies depending on various factors such as the size, stroke, type, and material of the cylinder. Moreover, the supplier or manufacturer’s reputation and quality also affect the price. Therefore, it is essential to compare prices from different sources and consider the overall value and reliability before making a purchase.

Conclusion

Stroke of Hydraulic Cylinder is a critical component of hydraulic systems that helps in transforming the pressure of fluid into linear motion. Whether you are a hydraulic enthusiast or a curious individual, understanding the stroke of hydraulic cylinders can help you gain a better insight into the working of hydraulic systems. Moreover, hydraulic cylinders offer numerous benefits over other types of linear motion systems, such as high force generation, smooth operation, consistency, precision, and control. Therefore, if you need to perform heavy-duty tasks that require consistent and precise motion, hydraulic cylinders are an ideal choice.

This post topic: Stroke